At NTECK, we lead the industry in innovative transmission solutions, crafting shifter towers and forks with cutting-edge technology and uncompromising quality. Our products are engineered for precision, durability, and maximum efficiency, ensuring smooth, reliable shifting and enhanced power transfer under all conditions. With advanced manufacturing and premium materials, NTECK delivers transmission components that set the standard for performance and longevity—because your vehicle deserves nothing less than the best.

At NTECK, we specialize in manufacturing high-performance shifter forks and towers that redefine the standards of precision and durability in the transmission industry. Leveraging advanced technologies such as plasma robotic welding, laser marking, end-of-line testing (EOL), injection moulding, induction hardening, distortion correction, and precision assembly, we ensure each component meets the highest benchmarks of quality and reliability. Our commitment to innovation and engineering excellence enables smoother gear transitions, enhanced power transfer, and extended product lifespan—delivering unmatched value to OEMs and automotive partners worldwide. With NTECK, you’re not just shifting gears—you’re shifting expectations.

Manual Transmission / Automated Manual Transmission (MT/AMT) Parts

Shift Tower Assy and child parts

Shift Tower Assembly

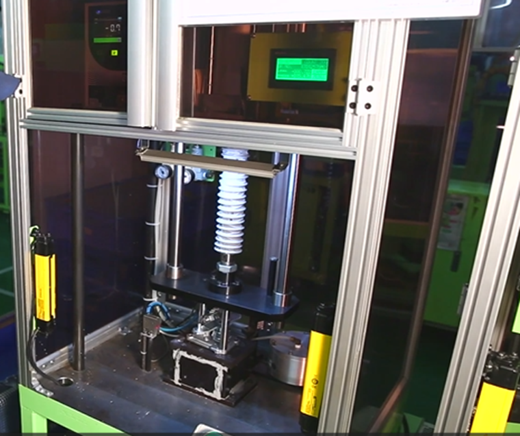

Our assembly process is fully automated, utilizing advanced robotics and AI-driven systems to ensure precision and consistency. This technology prevents all kinds of errors, including incorrect assembly and manufacturing defects, guaranteeing high-quality automotive components. By integrating automated inspection and intelligent quality control, we enhance efficiency while maintaining the highest industry standards.

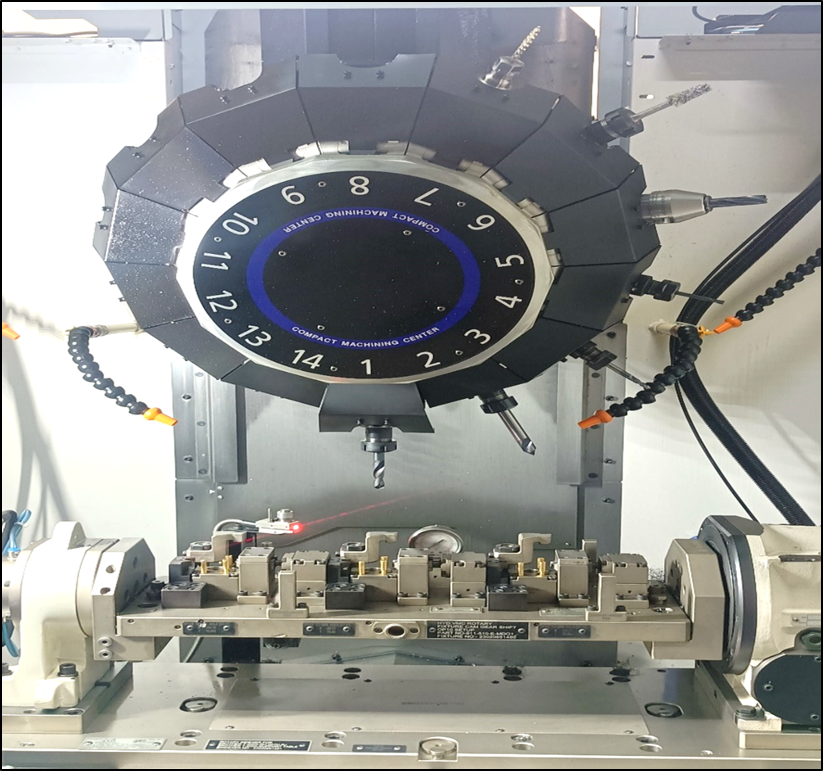

VMC Operation

Our production facility utilizes advanced Vertical Machining Centers (VMCs) to deliver precise and efficient machining operations. These state-of-the-art machines ensure high accuracy and consistency across a wide range of complex components.”

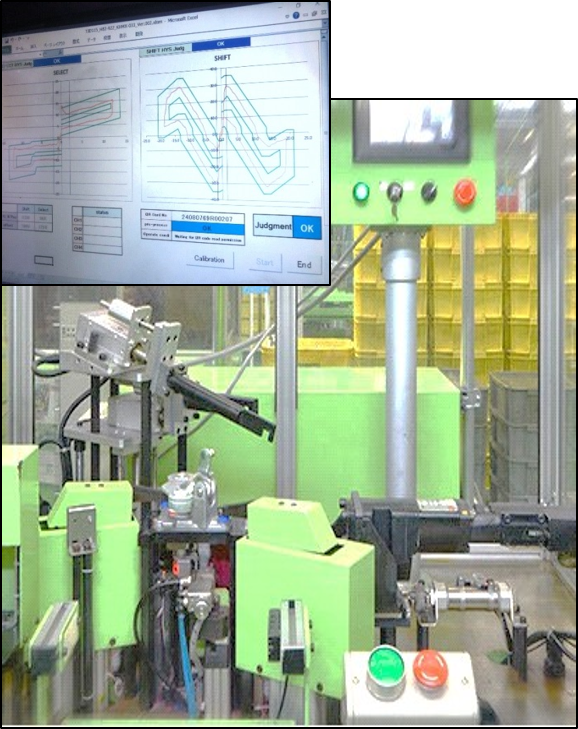

Automatic Measurement Test Machine

Automatic Measurement Test machine is for evaluating the overall performance of products after assembly. All these machines are designed and manufactured by KORITU IN Japan. We are checking the movement of all gears automatically verify the stroke from the neutral position, ensuring the accuracy and reliability of the assembly.

Automtaic Hysteresis Test Machine

Automatic Hysteresis Test machine is for evaluating shift feeling of products after assembly. All these machines are designed and manufactured by KORITU in Japan We are checking Automatically accurately Measure Shift & Select Load vs Displacement asper the Drawing Requirement

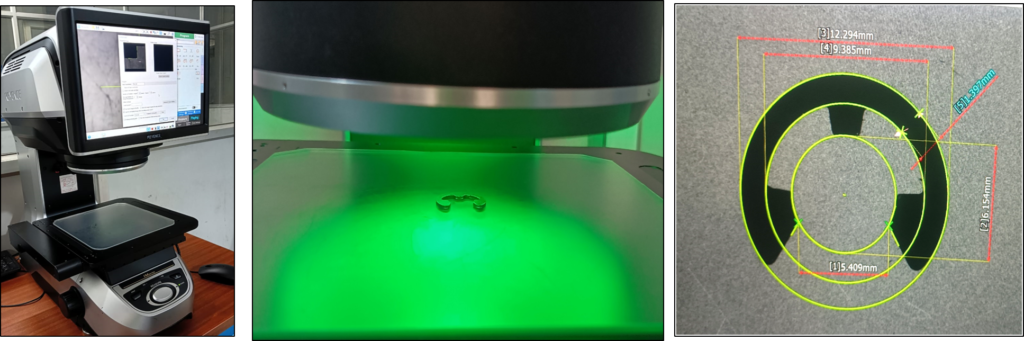

Optical Measuring Machine

We use Optical Measurement Machine(OMM) for meticulous inspection , ensure precise and accurate evaluation of our components . These advanced System enhance quality control and uphold our high standards of production .

Shift Fork Assy and child parts

Technlogy

Injection molding

Injection molding is a process for producing parts by injecting molten plastic material into a mold cavity, where it cools and hardens to the configuration of the cavity.

As for products required high strength and abrasion resistance property, we can provide products which satisfy required properties by using insert molding, which insert plastic resin into around metallic parts.

Assembly

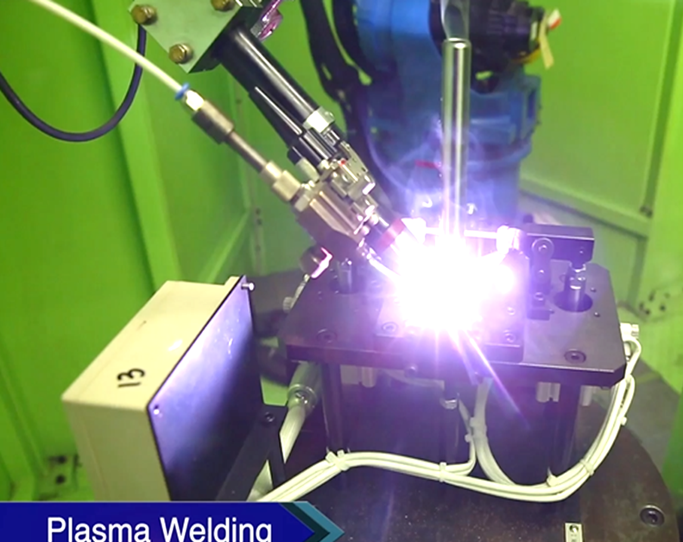

Welding

Welding is a process used for joining two metallic parts through the application of heat. We mainly adopt plasma welding among many types of welding. Plasma welding is an arc process in which a plasma arc is the source of heat. Comparing with tig welding, it has some merits such as deep penetration, less distortion caused by heat and faster welding speed.

Assembly

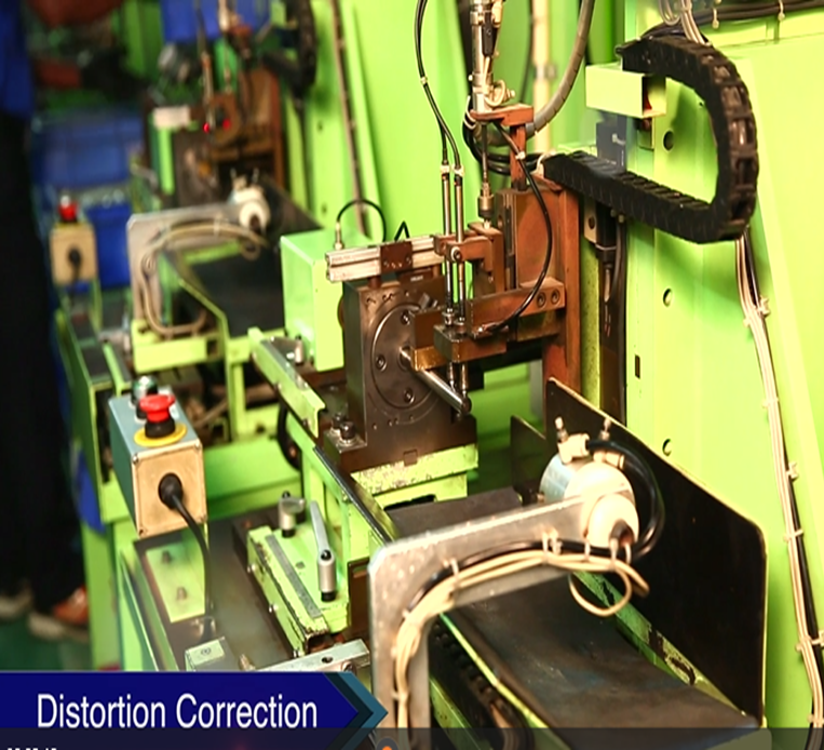

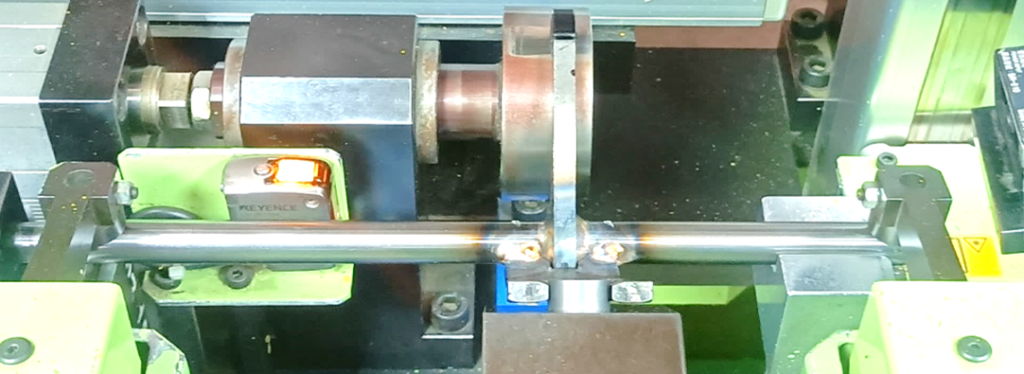

Distortion correction

Heat of heat treatment or welding causes distortion of metallic parts, for example bending or deformation. There is a possibility of the occurrence of a problem in quality if a distorted part is sent to the subsequent process or shipped to a customer as a finished part because most of our products are precision parts.

Therefore, the process to correct distortion is necessary. Distortion correction is performed to a shaft until its distortion becomes less than 0.1mm.

Technlogy

Eol

We ensure the quality of our products using advanced End-of-Line (EOL) machines that automatically check critical dimensions according to the drawings, ensuring each item meets our high standards for quality and reliability.”.

Technlogy

Laser Marking

We utilize advanced laser marking technology to generate precise and scannable barcodes on a wide range of components and materials, including metals, plastics, and coated surfaces. This ensures long-lasting readability even under harsh operating conditions such as heat, abrasion, and chemical exposure.Our automated laser systems enable fast, accurate, and repeatable barcode marking, making them ideal for applications requiring traceability, inventory management, and quality control in industries such as automotive, and manufacturing.

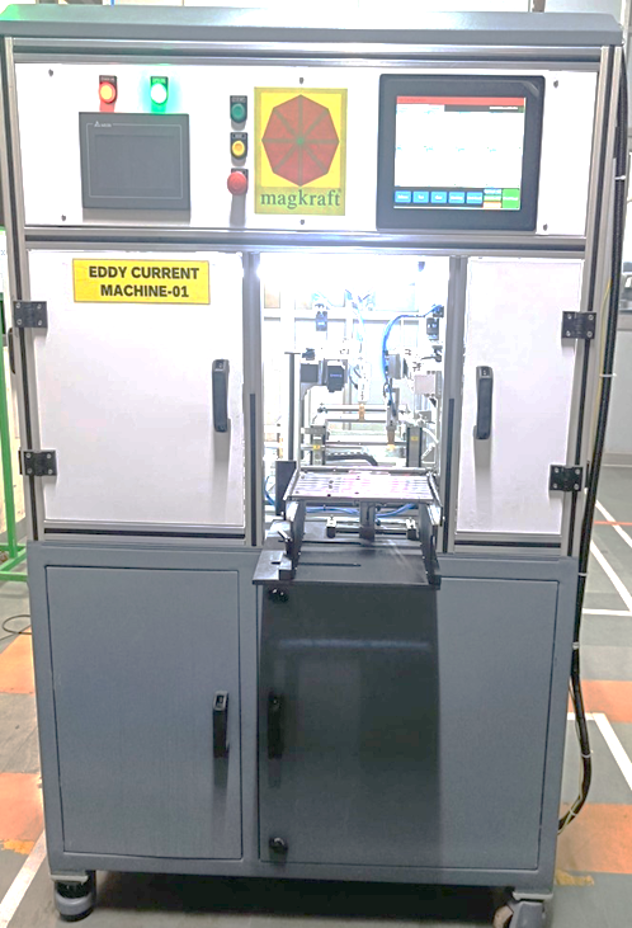

Eddy Current Machine

If Heat Treatment is not good result, this may cause problems in the market but we can not cut all parts. because after cutting, we can not use these parts Now we use advance Technology (Eddy Current Machine) for testing of Heat Treatment part without Cutting/Breaking. Therefore we can deliver our product without heat treatment issue

Technlogy

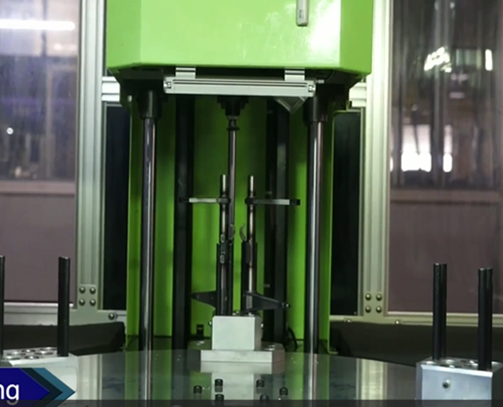

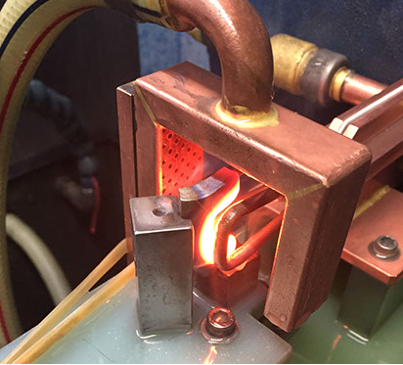

Induction hardening

Induction hardening is a process of heat treatment used for the surface hardening by heating the outer surface of the parts by applying high frequency induction current caused by high frequency electromagnetic induction action.

The surface of the component is hardened, but toughness of its core remains unaffected and therefore wear resistance and fatigue strength are increased. This is widely used for automobile parts which require high strength and high rigidity, and is applied to most of our shafts.

Machining center

Machining center is a kind of process method, which rotates various kinds of cutting tools set on its main axis.

The difference from lathe turning is that lathe turning rotates a piece, but on the other hand, machining center rotates a cutting tool. It has a characteristic that one machine can perform different types of processes. We adopt the optimal method according to the purpose such as high accuracy by one chuck operation or high productivity by production line.

Evaluation system / Measuring apparatus

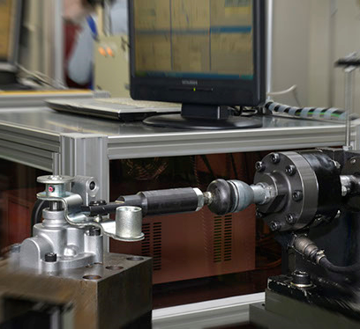

Shifting load measurement

Finger position measurement

Leakage test

Shifting load measurement

Strength test device

- We employ advanced technologies and precision testing equipment—including shifting load measurement, finger position measurement, leakage testing, endurance testing, and strength testing devices—to ensure the highest levels of product quality, performance, and reliability across all stages of development and production.